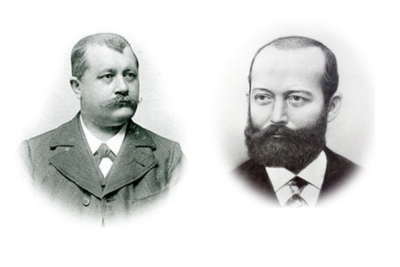

In the vaulted cellar of Villa Burger on Schonach’s Hauptstraße, which has been preserved to this day as a testament to the company’s 160-year history. The photo shows, from left to right: Manuel, Fabian, Thomas, Silke, and Josephine Burger. Thomas and Silke Burger are the fifth generation to run the traditional company, and Manuel and Fabian are already the sixth generation to work in the company. The historical portraits show the company founders Josef and Eugenia Burger.

1856

The founding years

Josef Burger, a native of Yach, moves from Schönwald to Schonach, where he marries Eugenia Kuner, adopts her son Hermann and sets up a foundry. After training as a founder, he was employed as a master craftsman at Vinzenz Siedle in Schönwald.

Josef Burger set up his foundry in a former farmhouse, now Villa Burger, in the center of Schonach. At the beginning, he mainly manufactured gear wheels for clockworks using the sand casting method. The company soon became called “Fabrik für Uhrenbestandteile & Metallgießerei” and employed eight people. Josef Burger was significantly involved in the industrialization of watchmaking in the Triberg/Schonach/Furtwangen region.

1879

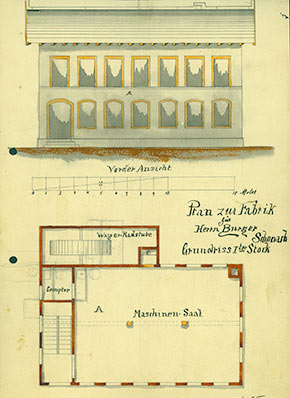

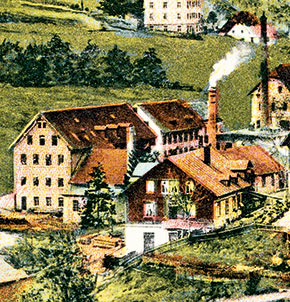

Construction of the new factory facing the stream

The continuous growth required a new factory in Schonach’s Untertal, one of the first in the Triberg/St. Georgen region. In addition to hydroelectric power, a steam engine supplied the required energy. The company had 20 employees, some of whom also came from the Elz Valley, the home of the company founder. As a result, the factory grew and with it the number of employees. Burger soon became one of the oldest and largest clock component factories in the Black Forest.

1885

Foundation of the company health insurance fund

The foundry work was hard and not without danger. From the beginning, Josef and Eugenia Burger were concerned about the health of their workers and founded a company health insurance fund. It aimed to improve treatment options and mitigate economic consequences of accidents and illnesses through affordable health insurance. The “BKK Josef Burger” existed in this form for 117 years.

On January 1, 2003, the BKK Josef Burger merged into the BKK Schwarzwald-Baar-Heuberg.

1872

The Hermann and Hartmann Burger era—two brothers on the road to success

Josef Burger’s eldest sons, Hermann and Hartmann, joined the company in 1872 and 1876 respectively. Hermann completed a commercial apprenticeship in Karlsruhe, and Hartmann an apprenticeship at the straw hat factory F. L. Sauter in his hometown of Schonach.

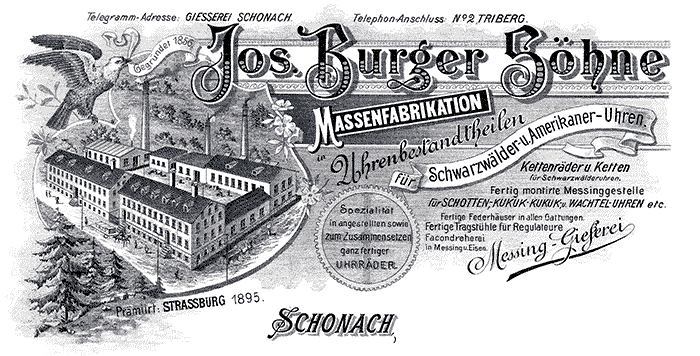

In 1886, two years before their father’s death and 30 years after the company was founded, they took over the business. They continued to run it under the name “Jos. Burger Söhne” in the legal form of a general partnership. The takeover value was set at 60,000 marks—a clear sign that the company had developed successfully and had a solid financial basis. The coming decades brought a steep upswing with several structural expansions. By 1913, the workforce had grown to 300 employees.

1884

The factory continues to grow

In the 1880s, “Jos. Burger Söhne” received a stately extension. Today, it is the oldest building in the Untertal site complex and still serves as an office wing. In 1889, a foundry hall was added—in a slightly different location—and in 1893 a fixed steam boiler was installed. In 1896, another building wing was added as an extension of the old factory.

In 1911, a tower was built in red clinker, which was decorated with a clock from the Schonach tower clock factory B. Schneider Söhne. This striking tower building is now an industrial landmark in Schonach.

1888

Death of the company founder Josef Burger

Company founder Josef Burger died at the age of 64 as a respected entrepreneur and citizen of Schonach. He was active in local and regional politics: as a local councilor, alderman in Triberg, and representative at the district health insurance fund. He was also nominated as an elector for the deputies to the 2nd Chamber of the Baden Estates. His broad social commitment was the foundation of the company’s tradition of responsibility for its workforce and fellow human beings, which continues to this day.

1890s

The portfolio broadens

In the late 1890s, the company increasingly expanded production. Until around 1890, the company almost exclusively produced watch components, watch chains, chain wheels, and spring barrels. In order to become less dependent on the watchmaking market, the company turned its attention to related manufacturing sectors by producing counters for gas and water meters, pressure gauges, and vacuum meters.

From 1908 onward, the Schonach company produced complete spring drives for speech machines: a young branch of business with great potential. Gramophone drives were in demand mainly from the emerging Berlin phonograph industry, but also from abroad.

1906

Construction of the Villa Burger

The success of the factory was also felt in private life: After the main building is demolished in the center of Schonach, Villa Burger was built on the same site. The client was Hartmann Burger, who still retained the vaulted cellar in which his father founded the foundry in 1856. His brother, Hermann, built a stately home on the factory site in Untertal.

The Villa Burger was the representative center of life for the factory owner’s family and also a hospitable social center of the village. It was also the home of Hartmann’s deaf-mute siblings Karl, Frieda, Rudolf, and Elise.

1910

Conversion into a GmbH (German limited liability company)

In 1910, the company changed from an OHG (general partnership) into a GmbH with a share capital of 800,000 marks.

In addition to the two brothers Hermann and Hartmann, Hermann’s son-in-law Franz Kramer became managing director.

After Hermann suffered a stroke, Franz Kramer took over an increasing part of the day-to-day business. The son-in-law proved himself and also participated in the social and political life of Schonach.

1914 to 1920

First World War

Around 300 people then worked for the company, which was one of the largest in the region. Everything changed with the outbreak of the First World War as a large part of the male workforce has to fight in the war. With a predominantly female workforce, Jos. Burger Söhne took up the production of war items.

The family suffered severe blows of fate: Hartmann’s son Arthur died as an officer in Flanders in 1918; he was supposed to run the company after his return. His son Ernst was imprisoned until 1920. In 1920, Josef Burger’s adopted son Hermann Burger died at the age of 66.

1920s

Ernst Burger became managing director

In 1922, managing director Franz Kramer died completely unexpectedly as a result of a ruptured appendix. The company lost a rising leader.

In 1923, Ernst, Hartmann Burger’s son, who had a stake in the company, became managing director alongside his father. During the inflation years, building (19) 23 was erected. Untertalstraße was relocated next to the factory premises and no longer cut through the factory site. As a result of the global economic crisis, the workforce had to be reduced from 400 to 250 people.

In 1936, shortly before her death, Hartmann and his wife Josefine Burger settled the inheritance by means of a transfer agreement. Ernst Burger became the main shareholder and sole managing director. His management tenure at Jos. Burger Söhne and SBS spanned 46 years.

1930s

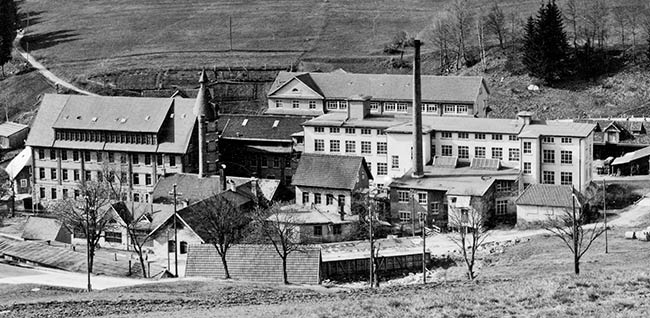

New construction and the Second World War

In 1937/38, a new building replaced the first and later extended factory building in Untertal. With the outbreak of the Second World War in 1939, the Schonach company also had to switch to armaments production. In 1940, the hydroelectric power plant was expanded.

A branch operation was set up in Steinach/Kinzigtal to ensure at least a partial continuation of production in the event of a bombing raid on Schonach. After the end of the war, the French occupation forces moved into Schonach. The newer machine stocks were dismantled.

1948

Zero hour and economic miracle

The company owed its renewed upswing to the changed economic-political environment after the war. Without the “economic miracle” after the currency reform (1948), the founding of the Federal Republic of Germany (1949) and the Marshall Plan aid, this would have been unthinkable.

Above all, they benefited from the great interest in cuckoo clocks, which goes back mainly to the American soldiers. It was not unusual for them to take two or three clocks home with them as a Black Forest souvenir.

1955

Creation of the new circular building

In 1955, the “Rundbau” (circular building) was built on the factory site. It was designed by the Freiburg architect Astfalck with a “sophisticated industrial architecture.” This was how the Landesdenkmalamt (State Office for the Preservation of Historical Monuments) judged the important buildings in Schonach in a present-day characterization.

The urgently needed new three-storey building provided around 1,500 square meters of new production space. This housed the stamping shop, a machine room, and assembly workstations.

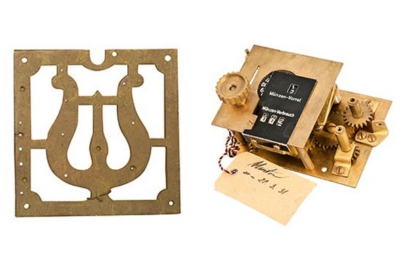

1955

The legendary “BUTOBA” tape recorder

The company was flourishing, but there was no sustainable success in all sectors. Gramophone production was dying down, and it had no chance without the combination of spring drive and electric motor (as at Dual in St. Georgen). On October 19, 1955, Ernst Burger applied for a patent for a transportable tape recorder which, thanks to its internal clockwork, could record without electrical power. The mains-independent tape recorder “BUTOBA” was Burger’s great hope and was temporarily exported to over a hundred countries. In the mid-1960s, despite all the technical perfection, the costly production was discontinued.

1956

Managing Director Rolf Burger

In 1956, Ernst Burger’s son Rolf joined the company. The trained toolmaker worked at Bosch in Stuttgart from 1949 to 1950 and attended the technical school in Stockach and the commercial school in Freiburg from 1953 to 1955. In 1954, he also gained personal experience in the important American market where he carried out repairs on mechanical mechanisms for US watch customers over a period of several months. In 1958, he became managing director alongside Heinrich Stoeckhert and his father Ernst Burger.

1958 to 1968

The division of the company

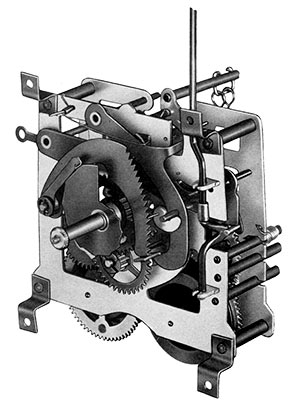

The business is divided into two independent companies: “Josef Burger Söhne” became “Burger Industriewerk” (BIW) and “Schwarzwälder Uhrwerke-Fabrik Burger Schonach” became today’s SBS-Feintechnik.

The SBS shareholders at the time were Ernst Burger, Rolf Burger, Gisela Schacht, Heinrich Stoeckhert, Leoni Haas, Gertrud Faller, and Rebstockwirt Bruno Schneider. SBS remained true to its original philosophy as everything continued to revolve around precision engineering. Schonach’s largest employer mainly manufactured mechanical clockwork mechanisms, but also assemblies and turn and gear parts. The workforce consists of over 300 qualified employees.

The company expanded by another 2,000 m².

After Ernst Burger’s death in 1968, his son Rolf Burger assumed the sole management.

1970s

Clockwork production dominates

In 1973, the workforce reached 535 people, the highest level in SBS history. Until the mid-1980s, the profitable clockwork mechanism business remained the main area of activity, accounting for over 70% of revenue.

In the SBS branch in Unterprechtal, watches and clockwork mechanisms were assembled from 1971, and search drives for car radios and drives for tachographs were also manufactured. At peak times, up to 40 people worked here.

The recruitment of guest workers, which began in the 1960s, was successful and in 1965 included 47 people; by 1973, the number had risen to 125. Almost half of the women employed in manufacturing were guest workers.

1980 to 1990

Full of visions for the future

In 1982, Thomas Burger, the fifth generation, joined the company. He transformed SBS-Feintechnik into a specialist for customized drive solutions that are in high demand in the technomotive and automotive sectors.

In 1983, SBS-Feintechnik acquired the insolvent Badische Uhrenfabrik Furtwangen (Baduf) and finally became the world market leader in the manufacture of mechanical clockwork mechanisms for cuckoo clocks.

In 1987, the building was extended. The five-storey Building 65 was extended by a new building with two stories. It creates a production area of 2,000 m².

1990 to 2000

Thomas Burger founded the BURGER GROUP

In 1993, Thomas Burger took over the management of SBS-Feintechnik.

As technical plastic parts are becoming increasingly important in the construction of drive solutions, Thomas Burger founded KBS-Spritztechnik. This was also the birth of the BURGER GROUP.

In 1999, KBS-Spritztechnik moved out of its rented premises and built a 1,200 m² production facility on Fabrikberg. Five years later, it expanded by 1,800 m².

Expansion increased the demand for labor. In order to offer them housing opportunities as well, the Burger Wohnungsbau-Gesellschaft invested in seven apartment buildings between 1957 and 1990. Today, 50 company apartments are available to SBS employees.

2000 to 2010

Strong growth

2001 saw the founding of KBS-Spritztechnik CH, SBS-Mechatronics, SBS-Mechatronics CH and Grässlin-KBS. The addition from 1987 was extended, creating a further 1,400 m² of production space. The production area, then a good 16,000 m², illustrated the sustained growth of SBS-Feintechnik.

In 2006, SBS-Feintechnik celebrated its 150th anniversary. The former clock component factory is one of the oldest companies in the Black Forest region of Baden.

The first decade of the 21st century was marked by a gratifying development in turnover and several awards. The BURGER GROUP can demonstrate future-oriented solutions in all divisions as both SBS-Feintechnik and KBS-Spritztechnik received multiple “TOP 100” and “TOP JOB” awards as well as the ASS award for their training concept. In 2009, SBS was also a “TOP INNOVATOR” and category winner at “TOP 100” in the category “Innovative Processes and Organization.”

Then in 2010, it won “TOP JOB Employer of the Year.” There was also the Schmidt College’s special “Health” award as well as the “365 Landmarks in the Land of Ideas” award and, once again, the “TOP INNOVATOR” award.

2010 to 2015

The BURGER GROUP combines seven brands

In 2011, SBS-Feintechnik opened a new plant in Triberg with 10,500 m² of production space.

In 2012, the Triberg-based WEDO-Antriebstechnik, with 26 employees, became a member of the BURGER GROUP. Today’s KBS-ANTRIEBTECHNIK is now a 100% subsidiary of the successful BURGER GROUP in Schonach under the management of Thomas Burger.

In 2014, the company Nepron in Kaznejov, Czech Republic, was integrated into the BURGER GROUP as “SBS-Nepron.” The core business of SBS-Nepron is the manual and semi-automatic assembly of electronic and mechatronic products in high volumes.

SBS-Feintechnik received the 2014 “Dekra Award” in the safety category. The Schmidt College’s “Management Prize” followed in 2015.

In 2015, Hugger GmbH, based in Deißlingen, became the sixth company to join the BURGER GROUP. The business was closed at the end of 2021.

“Leber Ingenieure” from Schwaig joined the BURGER GROUP at the end of 2015. The company has been offering services and products related to electronics for over 25 years: Circuit diagram and layout design, hardware, firmware and software development as well as complete product developments with all necessary approvals.

In 2016, SBS-Feintechnik was awarded the “Industry Prize Germany—Land of Ideas” and was awarded “ETHICS IN BUSINESS” for the fourth time in a row.

2015 to 2023

The BURGER GROUP continues growing

In 2017, the company SBS Drivetec Inc. was founded in Canada in Barrie, Ontario. Fabian Burger took over the leadership on site. With over 3,000 m2 of production space, the newly built plant was designed for high-volume production for the North American market. The most important product was actuators for the automotive industry.

In 2017, the BURGER GROUP took over the company Hock GmbH in Schönwald. Under the current name KBS-Stanztechnik GmbH, it is active as an internationally operating company in stamping and forming technology in both the automotive and non-automotive sectors. The topic of training continued to be a very high priority and SBS-Feintechnik was named “Germany’s Best Employment Trainer” by Capital magazine.

In 2022, the company acquired Ignaz F. Görlacher Blechformteile GmbH in Villingen-Schwenningen, now KBS-Blechformtechnik GmbH. The core competence lies in the manufacture of high-quality enclosures and sheet metal constructions for a wide variety of applications in the automotive, electrical, laboratory, and air-conditioning industries as well as in mechanical and equipment engineering.

Innovation continued to be driven forward and SBS-Feintechnik was awarded the title of “TOP 100 Innovator” several times. In 2022/2023, the company received the “Employer of the Future” seal from the German Innovation Institute and was awarded the “TOP Employer 2022/23” in the field of mechanical engineering and automotive technology by the DtGV.

In 2023, Fabian and Manuel Burger were appointed managing partners of SBS-Feintechnik alongside Thomas Burger in order to gradually transfer responsibility to the sixth generation.

While Fabian will be in charge of the mechatronic actuator segment in addition to the management of the plant in Canada, Manuel’s future focus will be on the technomotive segment in addition to his responsibility for KBS-Stanztechnik and KBS-Blechformtechnik.

The BURGER GROUP now comprises 11 companies at 8 locations in Europe and North America and employs a total of more than 1,200 people. Turnover rose to around EUR 200 million.